München & Starnberg

Beauftragen Sie die besten Makler für Ihre Immobilie

München & Starnberg

Beauftragen Sie die besten Makler für Ihre Immobilie

München & Starnberg

Beauftragen Sie die besten Makler für Ihre Immobilie

Immobilienmakler für München & Starnberg seit 15 Jahren

Rufen Sie uns jederzeit an: +49 (0) 89 380 79 948

Wollen Sie Ihr Haus, Ihre Wohnung, Ihr Grundstück oder Ihre Gewerbeimmobilie verkaufen, vermieten oder verpachten?

Wir erstellen ein Wertgutachten für Ihre Immobilie und stellen Ihnen einen zertifizierten Immobiliengutachter

Wir präsentieren Ihre Immobilie Tausenden von Immobilien-Investoren und Interessenten in der Umgebung wie auch bundesweit

Auch im Jahr 2022 wurde die FREITAG® Immobilienberatung mit ihren Standorten in München, Neubiberg und Starnberg erneut für ihre herausragenden Serviceleistungen mit dem bundesweiten Immobilien Dienstleister Award (IDA) belohnt.

Der Branchen-Award wird seit 2016 jährlich durch die Deutsche Immobilienmesse und den BVFI, Bundesverband für die Immobilienwirtschaft, an Top-Unternehmen vergeben.

Die Juroren des IDA bewerten die Kandidaten für den Award nach den Aspekten Zuverlässigkeit, Service für Kunden und Partner, ein ansprechendes und vielseitiges Angebot, Vertrauenswürdigkeit, Erreichbarkeit, Kommunikation und die Transparenz der unternehmensinternen Prozesse.

Wir erstellen ein individuelles Exposé mit einzigartigen Fotos Ihrer Immobilie oder stellen Ihr Bauprojekt bei Investoren und Geldgebern vor

Durch ein internes Auktionsverfahren bei der Besichtigung holen wir den besten Preis für Ihre Immobilie heraus

“Immobilienmakler FREITAG® holt bis zu 20% mehr aus Ihrer Immobilie heraus!” – Handelsblatt.com “Ihr Gewerbemakler für München, Starnberg und Region: Immobilienmakler FREITAG®!” – n-tv.de

Vereinbaren Sie Ihren unverbindlichen Erstberatungstermin mit unserem erstklassigen Team aus München!

Verkauf, Vermietung oder Verpachtung: Unser Privat- & Gewerbe-Immobilien-Portfolio zum Vermieten oder Verkaufen!

Nehmen Sie gerne Kontakt mit uns auf und lassen Sie sich von uns ganz individuell beraten. Wir sind Ihr Premium-Partner in der modernen Immobilienvermittlung.

Ihr Partner in München und am Starnberger See

Michael Freitag

Wir holen bis zu 20% mehr aus Ihrer Immobilie oder Ihrem Baugrundstück heraus!

Informieren Sie sich über unser internes Bieterverfahren bei geschlossenem Bieterkreis!

Telefonnummer: +49 (0) 89 380 79 948

Professionelle Immobilienbeteiligungen ab 50.000 Euro

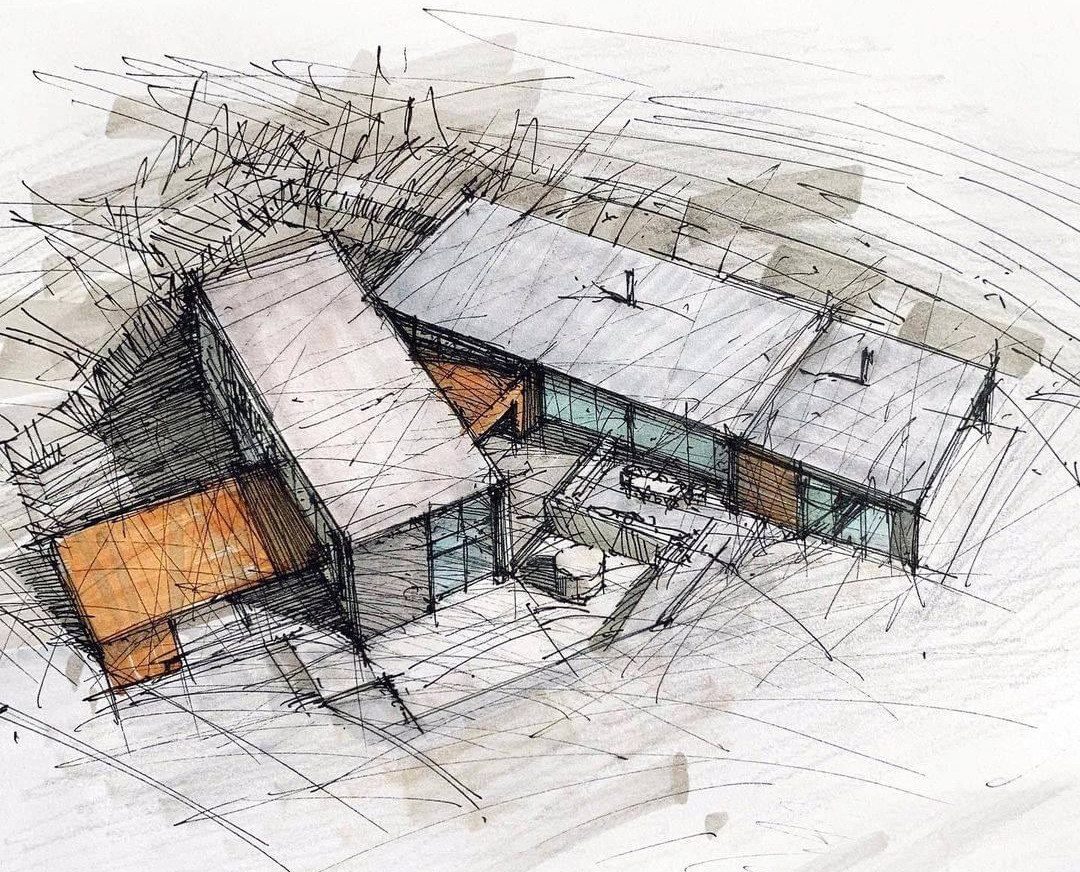

Über unser Partnerunternehmen mit derzeit knapp 400 Bestandsimmobilien und über 20 Jahren Erfahrung in der Planung und Abwicklung von Bauprojekten, haben Sie die Möglichkeit professionelle und notariell beglaubigte Immobilienbeteiligungen ab 50.000 Euro bei 4 Prozent bis 20 Prozent p.a. Mietrendite für sich zu sichern. Fordern Sie eine unverbindliche Beratung bzw. Präsentation bei uns an und lassen Sie sich unsere Referenzprojekte zukommen.

15 Jahre Immobilien-Erfahrung: Entwicklung, Bewertung & Verkauf

Unser aufgebautes Know-how: Hotels, Pensionen, Gastgewerbe, Wohnimmobilien wie auch Gewerbe- & Büroflächen

Immobilienexperten

Weit mehr als 15 Jahre “Real Estate”-Erfahrung, angefangen vom Bau von Immobilien, wie auch der umfangreichen Vermaklung von Immobilien, können Sie in unserer Immobilienkanzlei abrufen.

Marketingspezialisten

Profitieren Sie von über 10 Jahren Marketingerfahrung und ebenso von unserer Datenbank aus über 1.500 Immobilieninvestoren. Innerhalb kürzester Zeit verkaufen wir Ihre Immobilie.

Wir verkaufen in Rekordzeit und zum besten Preis über unser Bieter-Auktionsverfahren Ihre Wohnung, Ihr Haus oder Ihre extravagante Luxus-Immobilie in München, Starnberg oder am Starnberger See. Gerne verkaufen wir auch Ihre Immobilie in der näheren Umgebung von München bis 150 km Umkreis.

Strategie, Mission, Jobs & Ausbildung in der Immobilien-Kanzlei FREITAG®

Bewerben Sie sich gerne via eMail unter [email protected] als Immobilienmakler für die Region München, Starnberg, Starnberger See und Umgebung. Wir freuen uns aber auch über Initiativbewerbungen für weitere umliegende Landkreise der Region. Wir sind interessiert an selbstständigen Immobilienmaklern wie auch an angestellten Immobilienmaklern für unsere Agentur in München/Starnberg.

Sie wollen sich selbstständig machen als Immobilien-Berater bzw. als Immobilien-Makler und suchen eine Anlaufstelle, um eine seriöse und saubere Ausbildung zu absolvieren? Wenden Sie sich an [email protected] oder rufen Sie uns an! Gerne auch Quereinsteiger, die mit Menschen umgehen können, sich gepflegt kleiden können und ein Gespür für Marketing und Verkauf bzw. Vertrieb haben.

Ihr persönliches Wertgutachten!

Kostenlose Immobilienbewertung & Grundstücksbewertung völlig unverbindlich vorab: Jetzt kostenlos Ihre Immobilie oder Ihr Grundstück von unseren regionalen Immobilien-Spezialisten begutachten und bewerten lassen!

Unsere derzeit abgedeckten Immobilien-Standorte in München: Bogenhausen, Ramersdorf-Perlach, Trudering-Riem, Berg am Laim, Au-Haidhausen, Obergiesing-Fasangarten, Untergiesing-Harlaching, Altstadt-Lehel, Ludwigvorstadt-Isarvorstadt & Glockenbachviertel, Sendling, Schwanthalerhöhe, Sendling-Westpark, Thalkirchen-Obersendling, Hadern, Laim, Pasing-Obermenzing, Neuhausen-Nympenburg, Maxvorstadt, Aubing-Lochhausen-Langwied, Allach-Untermenzing, Milbertshofen am hart, Schwabing-West, Schwabing-Freimann, Feldmoching-Hasenbergl so wie Forstenried-Fürstenried-Solln für Ihre ausführliche Immobilienbewertung.

Unser neuer Standort in München - Berg am Laim - Immobilienmakler FREITAG® in Zusammenarbeit mit der ORANGE Immobilienagentur® in München

Gewerbemakler für Gewerbeimmobilien, Hotelmakler / Gastronomiemakler für Hotelimmobilien & Gastronomie bzw. Restaurants und klassischer Makler wie auch Grundstücksmakler für Ihre Immobilien und Grundstücke

Real-Estate-Dienstleistung in über 180 Gemeinden rund um München: Immobilienvermittlung, Immobilieninvestments und qualifizierte Beratung!

Immobilien im Fünfseenland: Kein Ende der Preisspirale in Sicht

Häuser, Wohnungen und Grundstücke werden in allen Gemeinden im Fünfseenland immer teurer und eignen sich deshalb besonders als intelligente Geldanlage. Das geht aus einem Marktbericht eines bekannten Starnberger-Maklers hervor. Neuvermietungen unter 10 Euro pro Quadratmeter gibt es kaum noch. Schon seit einigen Jahren kennen die Immobilienpreise im Fünfseenland nur eine Richtung: steil nach oben, und das möglichst schnell. Auch wenn der Preisanstieg nicht mehr so rasant ausfällt wie in den Jahren zuvor, so wird sich an der grundlegenden Richtung so schnell nichts mehr ändern. Davon geht Makler Florian Raffelt aus, der Geschäftsführer der Starnberger See Immobilien GmbH und Co. KG. Das Makler-Unternehmen mit Sitz in Possenhofen hat jetzt seinen neuen Marktbericht für die Kommunen des Landkreises herausgegeben. Den Marktbericht mit allen Daten und Fakten gibt es hier nachzulesen.München Nord, Ost, Süd, West oder Starnberg / Starnberger See

Gerne stellen wir Ihnen für alle 25 Münchener Stadtbezirke einen Immobilienmakler – Bogenhausen, Ramersdorf-Perlach, Trudering-Riem, Berg am Laim, Au-Haidhausen, Obergiesing-Fasangarten, Untergiesing-Harlaching, Altstadt-Lehel, Ludwigvorstadt-Isarvorstadt & Glockenbachviertel, Sendling, Schwanthalerhöhe, Sendling-Westpark, Thalkirchen-Obersendling, Hadern, Laim, Pasing-Obermenzing, Neuhausen-Nympenburg, Maxvorstadt, Aubing-Lochhausen-Langwied, Allach-Untermenzing, Milbertshofen am hart, Schwabing-West, Schwabing-Freimann, Feldmoching-Hasenbergl so wie Forstenried-Fürstenried-Solln. Sprechen Sie uns an bezüglich Immobilienbewertung, Erstellung eines Exposé, Beratung im Bereich Immobilienankauf und mehr.